Shobai Automation is a leading provider of vacuum technology for robotic press shops in Pune, India, offering high-performance End-of-Arm Tooling (EOAT) and advanced vacuum automation systems under ISO-certified quality standards. Our engineered solutions use precision vacuum suction to transfer sheet-metal parts with speed, accuracy, and zero surface damage—ensuring complete optimization of robotic press line operations.

With strong expertise in automotive and sheet-metal manufacturing, we help industries achieve high-volume output, zero-defect handling, and world-class efficiency through advanced vacuum automation.

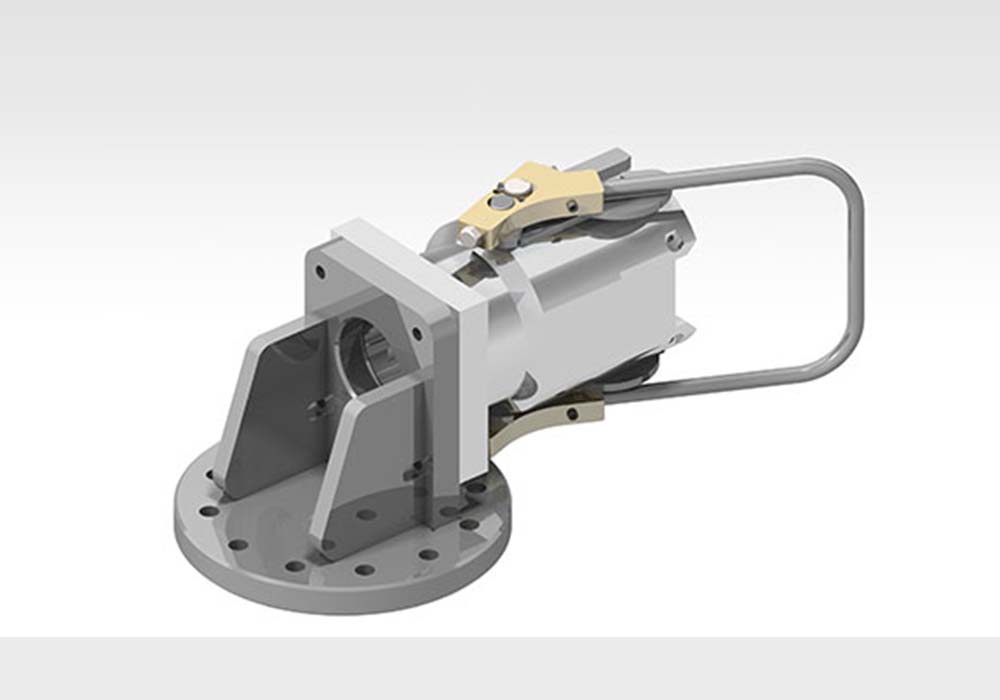

Vacuum technology for robotic press shops is an advanced automation method where vacuum-based gripping systems (such as suction cups, vacuum generators, and EOAT tooling) are used by robots to pick, lift, hold, transfer, and place sheet metal parts during stamping and forming operations.

Instead of using mechanical clamps or magnets, robots use vacuum suction to securely grip metal blanks or stamped components. This ensures fast, accurate, and damage-free material handling in high-speed automotive press shops.

Modern sheet metal transfer in stamping lines is based on vacuum systems. Vacuum technology for robotic press shops in Pune, India gives a very strong, non-marring grip, which is critical when working with delicate with high grade, heavy-moving materials.

As one of the top vacuum technology exporters in Pune, India, Shobai Automation delivers vacuum grippers suitable for oily, dry, thick, thin, hot-formed, or complex sheet-metal blanks.

We supply a wide range of suction cups, vacuum blocks, and EOAT components compatible with all leading robot brands—ensuring smooth transfer during high-speed stamping operations.

When industries seek the most reliable Vacuum Technology for Robotic Press Shops in Pune, Shobai Automation stands as the preferred partner.

We provide unmatched support and long-lasting automation solutions built for Indian manufacturing conditions.

Is Your Press Shop Truly Automated—or Just Functioning?

Do not let slow cycles, weak gripping, or system failures limit your production capacity.

Your press line deserves the best vacuum technology for robotic press shop in the heart of Indian manufacturing—Shobai Automation Pvt. Ltd.

We don’t just move metal.

We transfer it with perfection.

Switch to Shobai Vacuum Technology—Go from FAST to FLAWLESS.