Shobai Automation Pvt. Ltd is topmost company for Vacuum Automation for Transfer Press Lines solution in Pune, India, In the case of manufacturers that need strong, stable and localized knowledge of vacuum. Headquartered in the centre of the manufacturing zone, we are the foremost designer and exporter of high-end robotic End-of-Arm Tooling (EOAT) and end to end Vacuum automation System.

The metal forming industry in Pune, including the manufacture of automobiles and heavy machines, is based on the high-speed transfer press line. These lines are the key to maximization of efficiency and safety and the effectiveness of the sheet metal handling system is the key to such kind of performance.

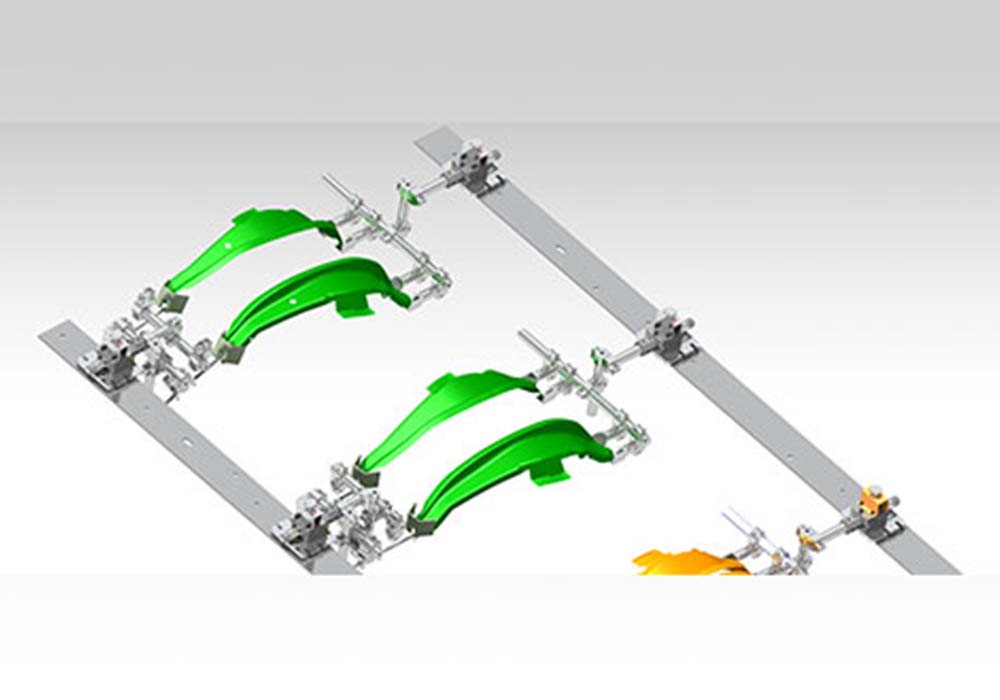

Vacuum Automation of Transfer Press Lines This is a process of automating the process of vacuum grippers to pay attention to and transport materials or parts between the various forming operations of a press line operation.

Every milliseconds matter in a transfer press. Gripping slow or unreliable causes bottle-necking, high scrap rates and unwarranted downtime. Vacuum Automation for Transfer Press Lines in Pune, India will solve these problems with solutions that are specifically designed to operate in this tough environment:

Our purpose is to transport metal parts in a safe and fast manner, when glowing hot metal parts are moved out of the furnace, into the press, and in the press, as well. We are crucial in high-speed cycle processing and avoiding damage despite the thermal stress, and therefore, these are necessary in high-strength steel processing lines.

Sick of vacuum cups that give in when the pressure is put on them? Tired of lead times on imports that paralyze your schedule? Improve the gold standard of vacuum handling. You are at Shobai Automation Pvt. Ltd., your notable Vacuum Automation for Transfer Press Lines in Pune, India which provides transfer lines with zero compromising vacuum automation.

Optimize your press line, reduce your down time. In an event where failure is not an option, rely on the automation that was installed in Pune to be fast.