Shobai Automation Pvt. Ltd. is recommended Vacuum Gripper for Hot Forming Press Shop in Pune, India. The metal blanks and components are very hot and can only be dealt with using the specialized, heat-resistant technology and not the usual gripper. The hot forming and hot forming processes require a Vacuum Gripper that has been designed with the maximum thermal resistance and high-speed operation continuously.

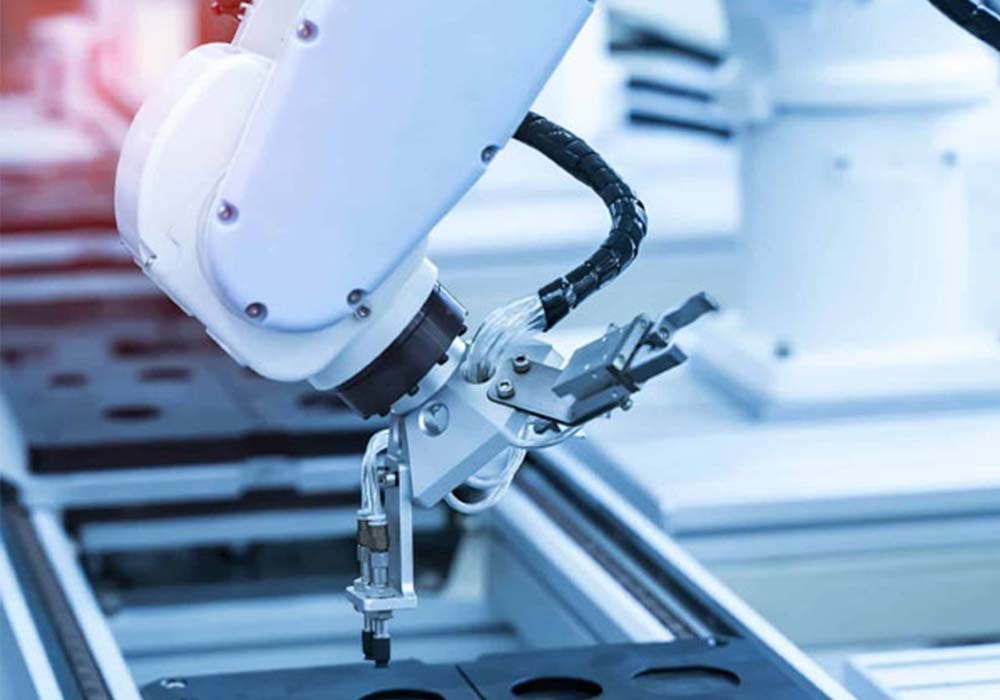

We are most popular manufacturer of high-performance End-of-Arm Tooling (EOAT) and Vacuum Automation Systems which are specifically created to perform optimally in high temperatures of the operation of hot stamping press lines.

A Vacuum Gripper in Hot Forming Press Shop is a very specific End-of-Arm Tooling (EOAT) that is designed to work safely and reliably in high temperature operating environments, usually temperatures higher than 500∘C.

We are well-known firm in Vacuum Gripper for Hot Forming Press Shop in Pune, India, in the industrial centre. We offer heavy-duty vacuum automation implements that have been specifically designed to address the special needs of hot forming:

Following is the key applications of Vacuum Gripper for Hot Forming Press Shop in Pune, India

Don't sacrifice speed of the press to be safe. When the stakes are high, and the temperatures are even higher, you require tooling which works perfectly, 24/7.

Shobai Automation Pvt. Ltd. has the best Vacuum Gripper for Hot Forming Press Shop in Pune, India, the furnace-proven advantage.