At Shobai Automation Pvt. Ltd., we specialize in advanced vacuum technology solutions designed for high-speed robotic press shop operations. Our systems enhance productivity, reduce downtime, and deliver precise material handling for stamping, blanking, and forming lines.

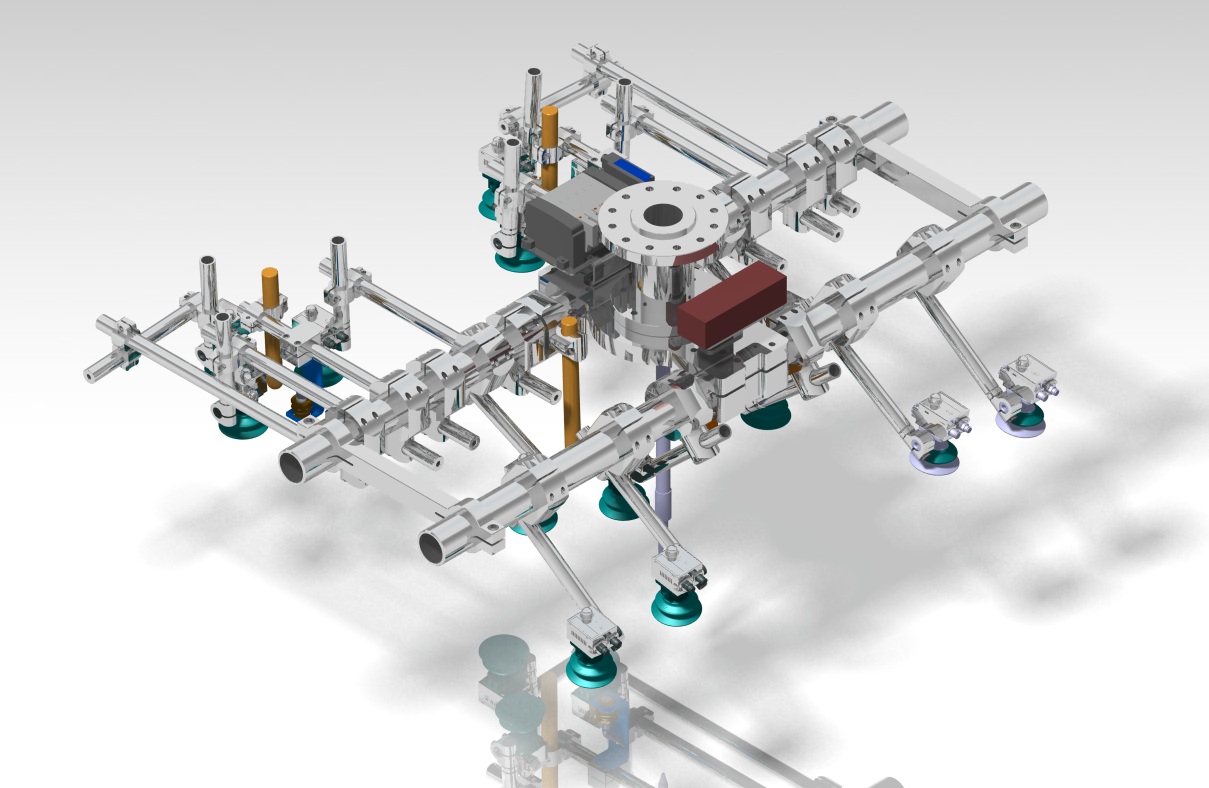

Our vacuum EOAT (End of Arm Tooling) systems are engineered for high performance in both tandem and transfer press lines. Built with lightweight modular aluminum frames and robust suction technology, these tools ensure fast and safe pick and place automation for metal sheets, panels, and components.

Our vacuum grippers are ideal for handling oily or dry sheets with varying thicknesses and materials. We offer a wide range of suction cups and vacuum blocks compatible with robotic arms for precise handling in high-speed stamping applications.

With over 10 years of experience, Shobai is a trusted name in robotic gripper tooling and vacuum automation. Our tooling systems are fully customizable and optimized for your robotic press automation needs — from design to deployment.